Description

Manual Description:

Number of Pages: 63

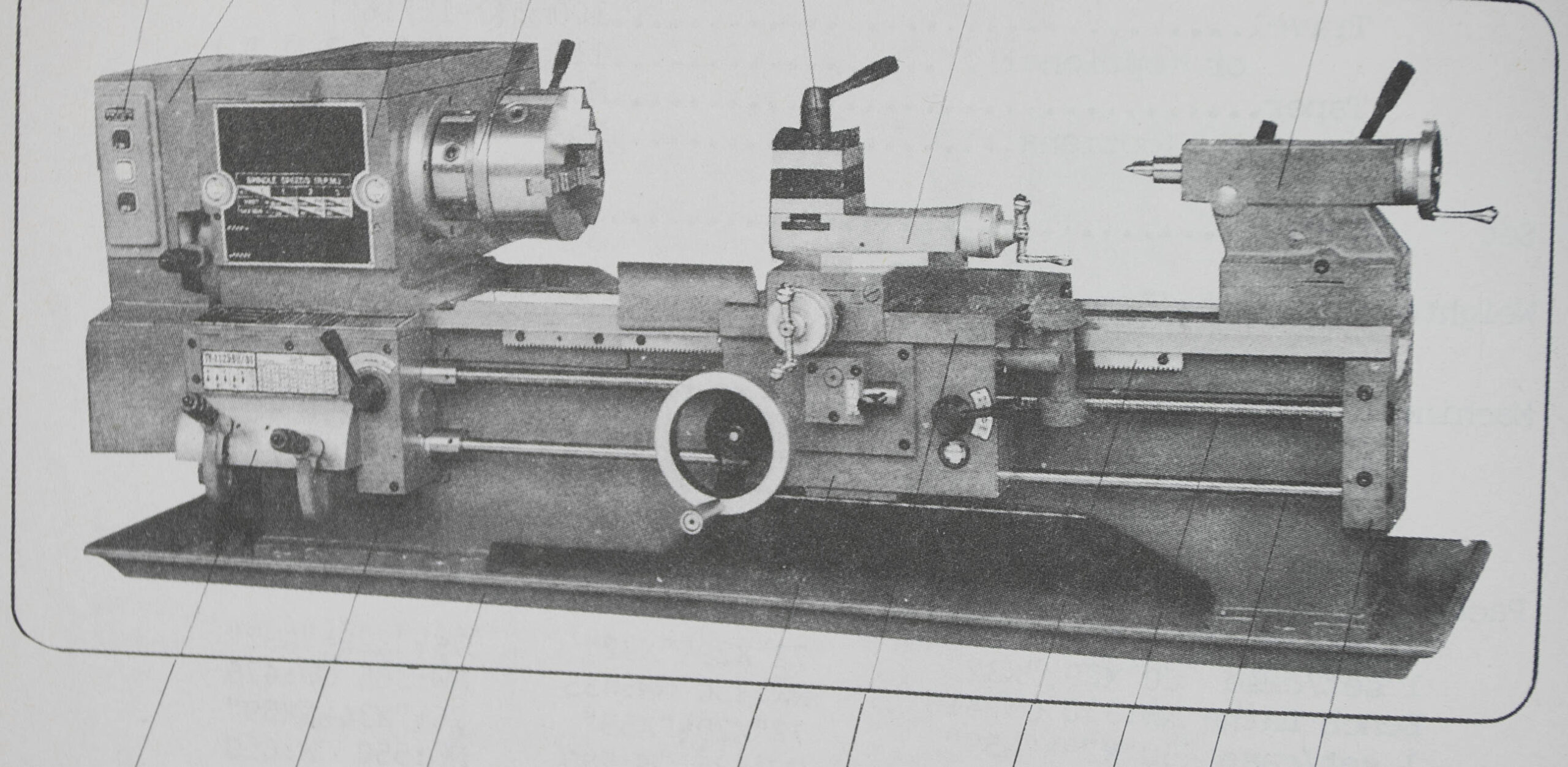

This is a reproduction, not a photocopy, of a Asian 13×25 13×36 13×40 13×45 Metal Lathe Instructions and Parts Manual. This machine is manufactured in Asia and has been sold under many different names including: JET, Grizzly, Enco 110-2031, Sharp, MSC, etc… This manual contains information on setup, lubrication, maintenance, and controls as well as a complete parts list and exploded views and adjustments. For an Asian manual this is put together well, and it covers a lot more than usual.

Known Models:

Enco 110-2031

BD-1325R

BD-1336R

BD-1340R

Paykel Engineering, TY-1340BH

Sharp 1340CU

JET 1240PY

Specifications:

Capacity & Dimensions

Swing

Over bed………………………………..330mm(13″)

Over cross slide…………………….198mm(7-25/32″)

In gap Diameter (optional)…………….476mm(18-3/4″)

Length (optional)………………….146mm(5-3/4″min.)

Center

Height…………………………………166mm(61/2)

Admits between (BD-1325R)…….628mm(24-23/32″)

(BD-1336R)………….915nm(36″)

(BD-134OR)…….1035rrm(40-3/4″)

Bed Width…………………………187mm(7-3/8″)

Length (BD-1325R)………….248mm(49-l/8″)

(CBD-1336R)…..1535rrm(60-3/8″)

(BD-1340R)…….1655mm(65-l/8″)

Height…………………………….290mm(ll-13/32″)

Drive……………………..Motor via belts & pulley

Motor For main spindle……2HP, 3ph or 2HP, or lHP, lph

Headstock

Spindle Bore………………………39mm(l-17/32″)

Nose…………………A.S.A. M. TYPE, 21/4-8 T.P.I.

or (optional)…………………Dl-4″ ASA std.

Taper in nose…………………………..No.5 Morse

in sleeve……………………..No.3 Morse

Speeds Number……………………………….12

Range…………………60-1240 r.p.m.

Carriage & Compound

Cross slide Width……………………118mm(4-5/8″)

Travel ……………160mm(6-5/16″)

Compound rest Width……………………….76mm(3″)

Travel………68mm (2-11/16″)

Lead screw Diameter……………………22mm(7/8″)

Thread…….8 T.P.I, or 3mm pitch

Feed rod Diameter…………………….19mm(3/4″)

Tailstock Quill

Taper………………………………….No.2 Morse

or (optional)………………………….No.3 Morse

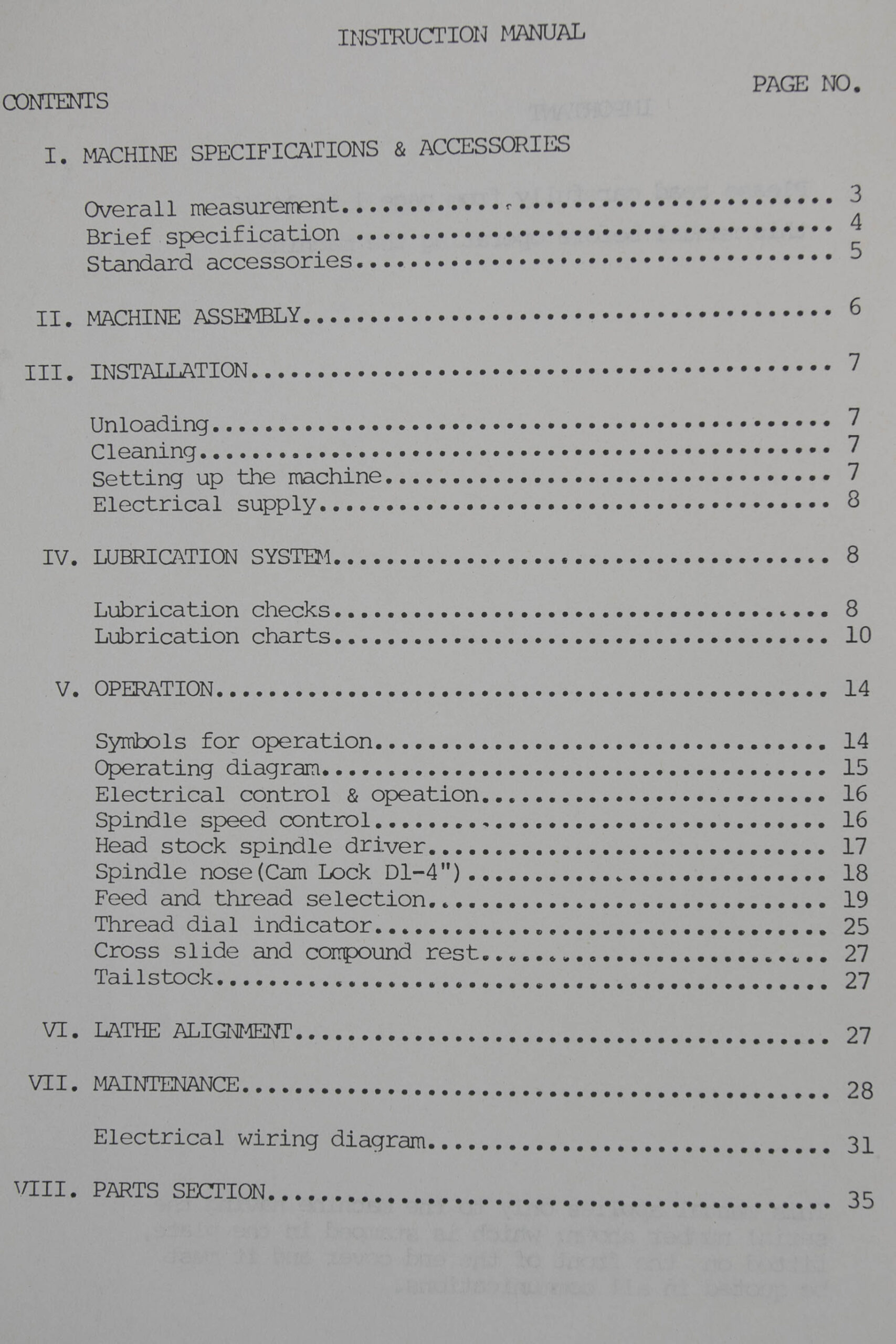

Contents:

Overall measurement……………………………..3

Brief specification……………………………..4

Standard accessories…………………………….5

II. MACHINE ASSEMBLY…………………………….6

III. INSTALLATION……………………………….7

Unloading………………………………………7

Cleaning……………………………………….7

Setting up the machine…………………………..7

Electrical supply……………………………….8

IV. LUBRICATION SYSTEM…………………………..8

Lubrication checks………………………………8

Lubrication charts……………………………..10

V. OPERATION…………………………………..14

Symbols for operation…………………………..14

Operating diagram………………………………15

Electrical control & operation…………………..16

Spindle speed control…………………………..16

Head stock spindle driver……………………….17

Spindle nose (Cam Lock Dl-4″)……………………18

Feed and thread selection……………………….19

Thread dial indicator…………………………..25

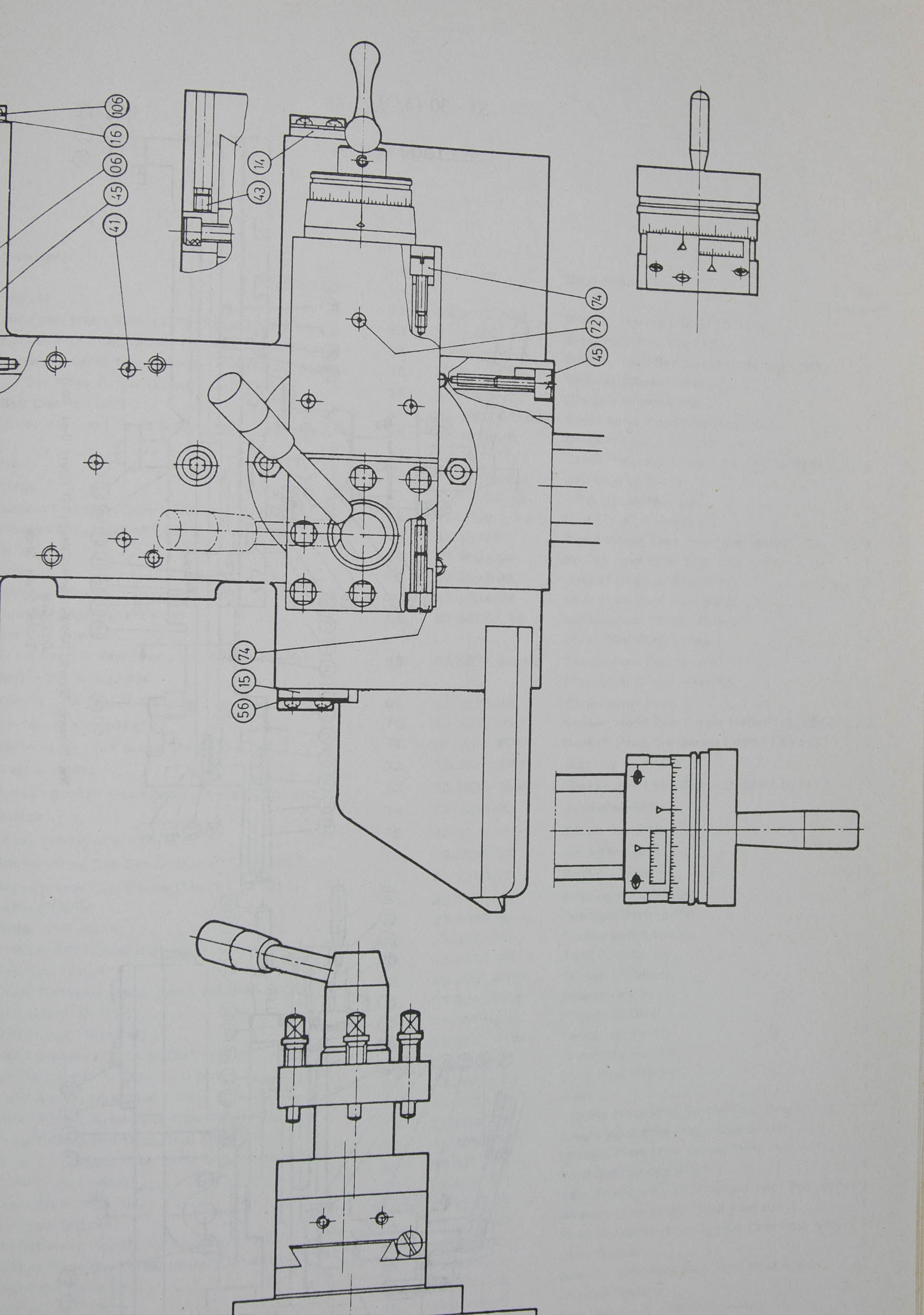

Cross slide and compound rest……………………27

Tailstock……………………………………..27

VI. LATHE ALIGNMENT…………………………….27

VII. MAINTENANCE……………………………….28

Electrical 1 wiring diagram……………………..31

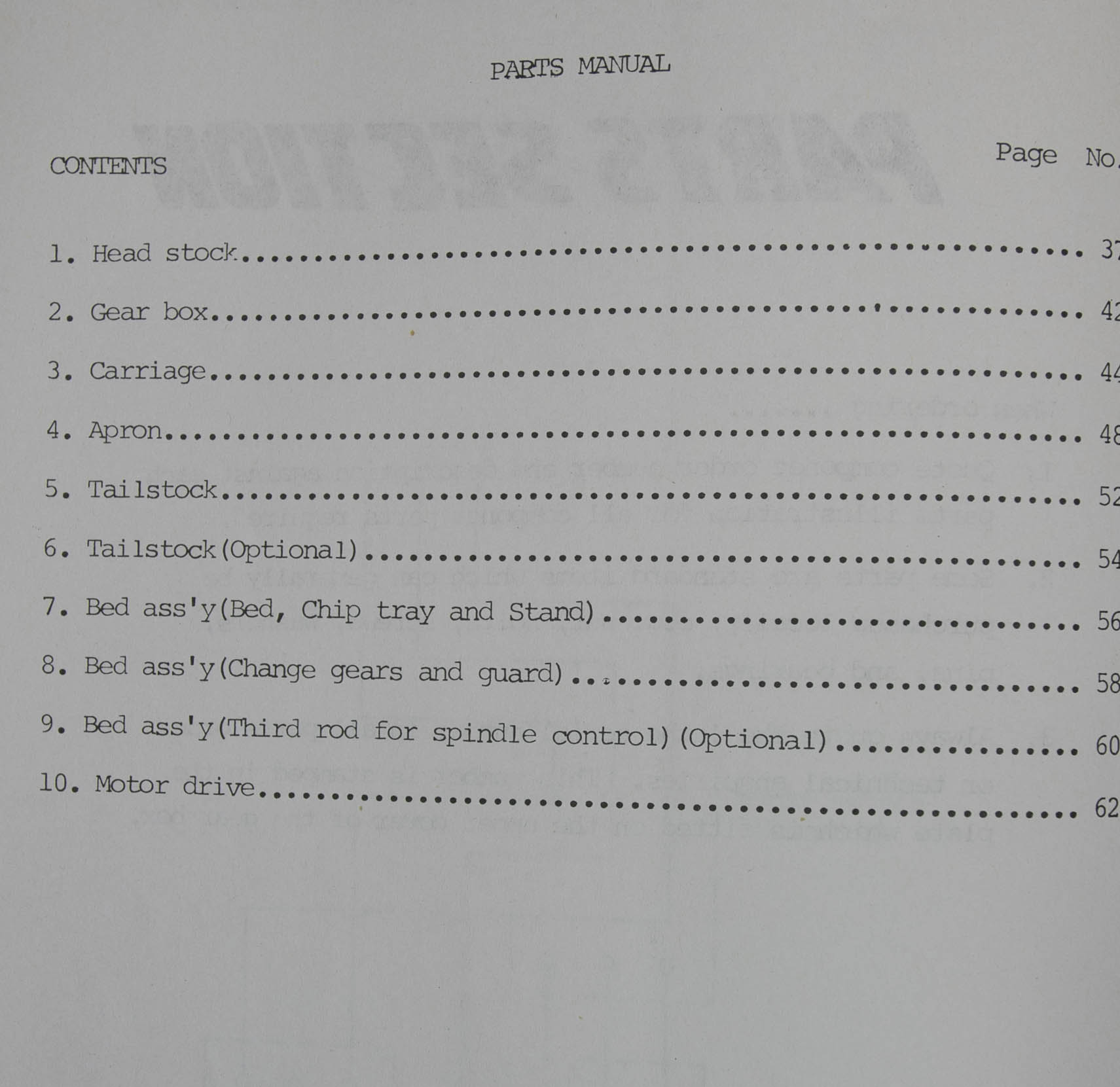

VIII. PARTS SECTION…………………………….35

Head stock…………………………………….37

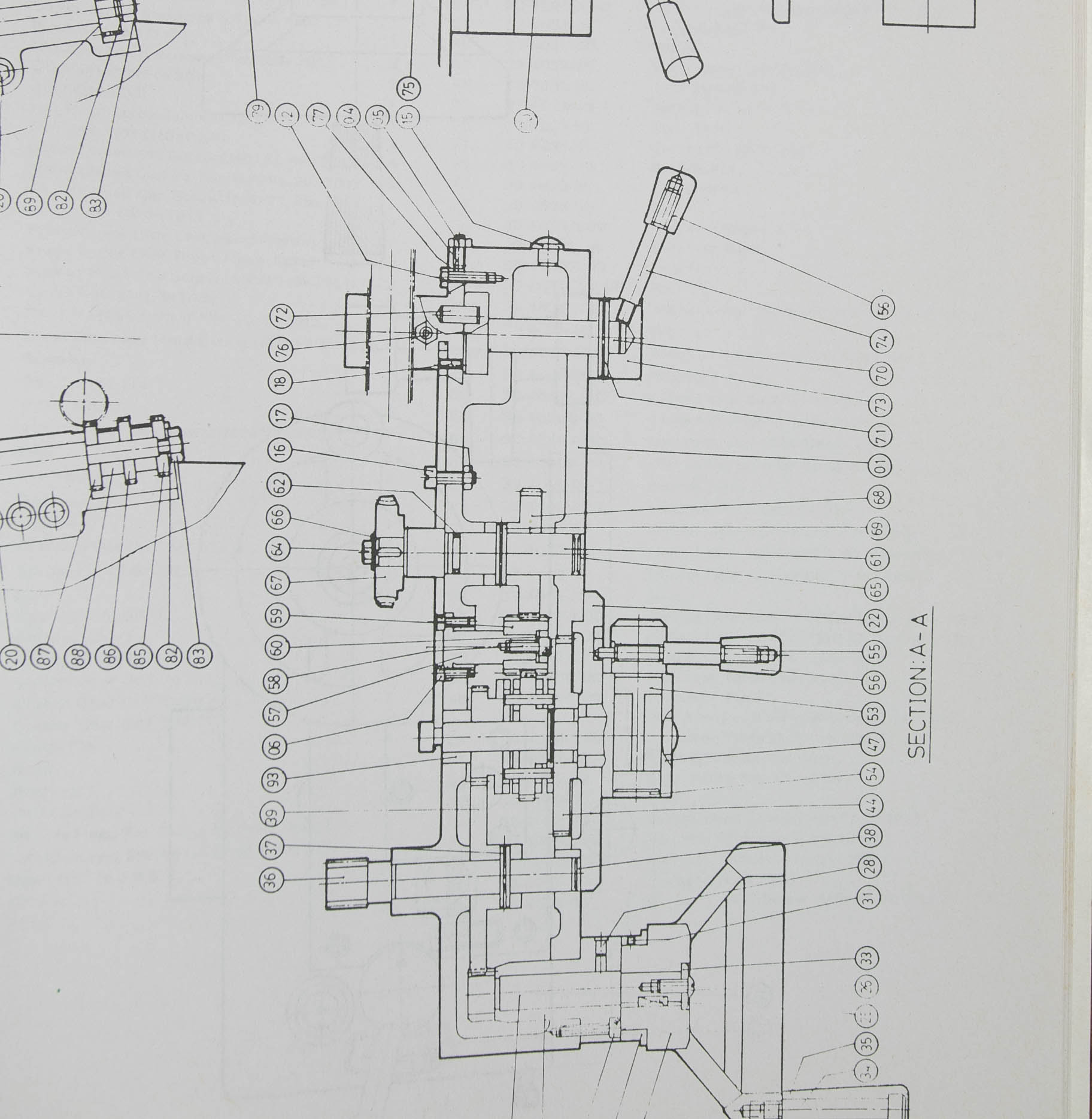

Gear box………………………………………42

Carriage………………………………………44

Apron…………………………………………48

Tailstock……………………………………..52

Tailstock (Optional)……………………………54

Bed ass’y(Bed, Chip tray and Stand)………………56

Bed ass’y (Change gears and guard)……………….58

Bed ass’y(Third rod for spindle control)………….60

Motor drive……………………………………62

Reviews

There are no reviews yet.